Brick, Flame, & Steel:

The story of building the Campfire Grill oven, 35 years in the making.

In 1987, Starr Teel returned to his summer-camp home of Flat Rock, NC to head up the renovation of the Kenmure Clubhouse, where the “cookhouse” (what is now the Grill Room) still stood separate from the main estate. Inspired by ovens he had seen in Italy as well as the historic fireplace still in the house of Dr. King, Teel pursued what has become a characteristic drive of his, to build something that’s never been built before, the first commercial wood-fire oven in North Carolina. Teel has since gone on to build 5 commercial wood-fire ovens, including that of Camp Falling Creek, Hubba Hubba Smokehouse, and the Flat Rock Village Bakery. His favorite though, the oven that he claims the experience of all the others has led to, is the one that now stands as the heart of Little Rainbow Row’s newest eatery, Campfire Grill.

Teel at camp square dance in 1977

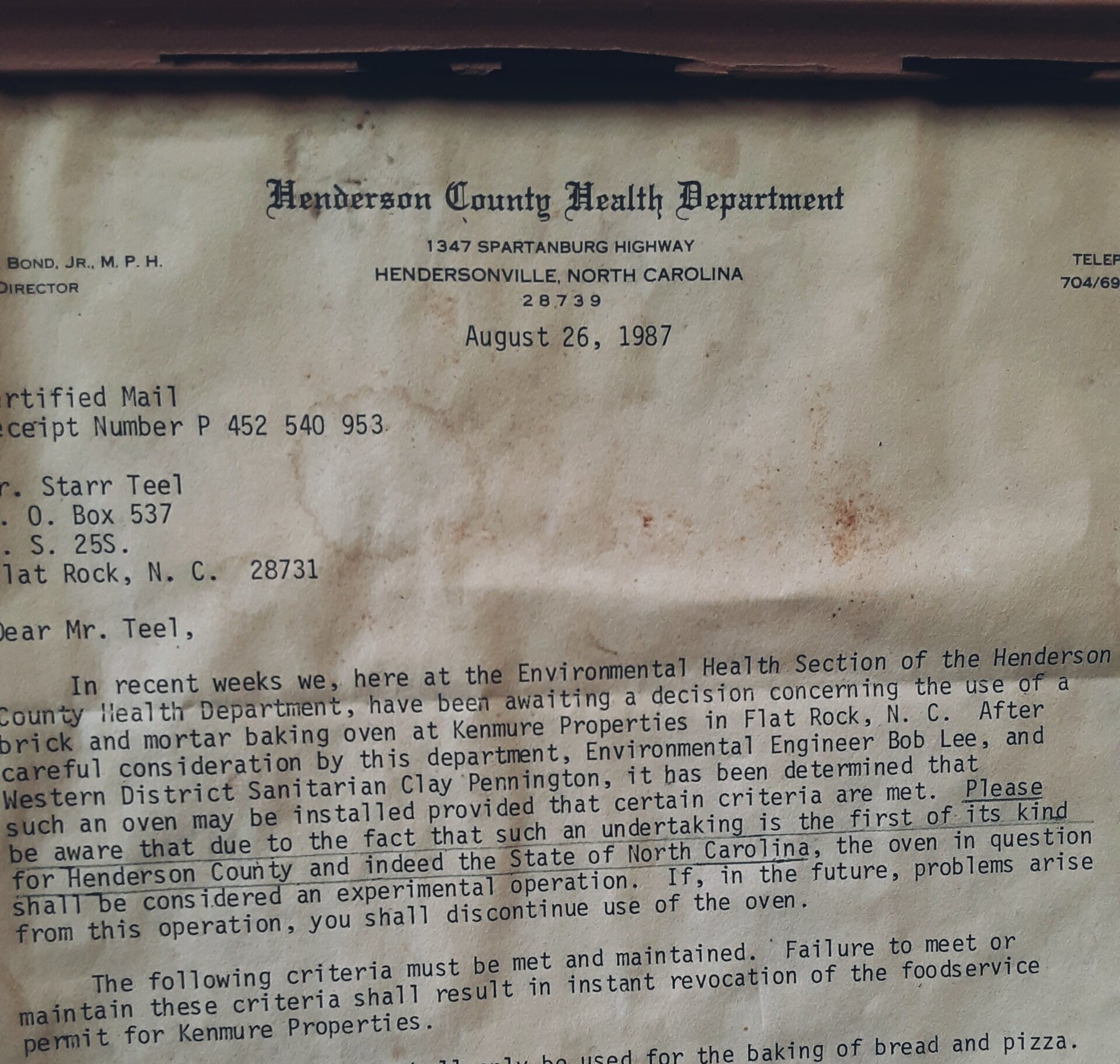

“Please be aware that due to the fact that such an undertaking is the first of its kind for Henderson County and indeed the State of North Carolina, the oven in question shall be considered an experimental operation.”

— Henderson County Health Department to Starr Teel August 26, 1987

The Team

If you ask Starr Teel how he accomplishes what he does, he will inevitably answer, “by surrounding myself with smart, caring, passionate people and asking questions.”

Government certified welder for nuclear reactors, amphibious and armored personnel carriers, welder extraordinaire, and, most recently, Campfire Grill’s wood-oven expert Jack Nash.

Jack Nash, of Nash Welding, welding on the custom made doors to the oven, which he crafted along with all of the steel and aluminum used in Campfire Grill, from our flower vases to the custom aluminum framed chimney, pictured below.

Rick & Drew Metcalf, our overall master craftsmen father-son duo, laying Super Duty 3” Brick on hearth and medium duty brick walls, bound not by masonry cement, but gray refractory high temp mortar which gets stronger under high temperatures.

Rick Metcalf installing ceramic blanket.

Nash insulated oven doors.

Wood, brick, & steel multi-talented Drew Metcalf finishes welding connections of smoker framework.

Nash welded a trough around the entire circumference of the chimney for insulation, as well as a luge to redirect any water out the rear of the chimney, protecting both the flames of the fire and the insulation inside the oven.

One of the primary forms of insulation we used is this highly castable insulation, which rather than adding water to (creating a more cement-like substance) we left in its’ sand-like form to act in conjunction with the air in the gaps to break any heat conduction.

The Materials

Since building the Kenmure oven, the materials for all of Teel’s ovens have been provided and consulted on by Larkin Refractory Solutions, headed up by Jim Wunch.

Jim Wunch has been the owner of Larkin Refractory Solutions since 1994. The firm was started in 1976 by John Larkin and on his untimely passing was then acquired by Jim.

Jim is a graduate of Clemson University with a BS in Ceramic Engineering in 1971. Throughout his professional career, he has been involved in all facets of the refractory industry. Beginning in raw material characterization and moving to product development enabled him to transition into sales and marketing. Later he was a plant manager, director of Corporate quality, and a senior executive responsible for sales, marketing and operations of two plants. Jim has traveled extensively throughout his career to visit and consult with most refractory consuming industries worldwide. As a deep thinker, Jim has come up with numerous cost effective solutions to solve thorny problems affecting these industries.

Larkin Refractory Solutions is based out of Lithuania, GA 800.898.4532

The hybrid nature of the Campfire oven makes it unusual, having the flu at the rear rather than the front and building the arch higher than standard not only provides space for racks to smoke fish and meats, but also facilitates bigger fires, the long-burning coals of which are then repurposed to fuel our Santa Maria wood-fire grill.

Jet High Duty 3” Bricks make up the arch of the traditional Beehive oven. Our arch is built higher than a traditional pizza oven, making the heat from the fire refract at lower temperatures that sustain our “low & slow“ philosophy for meats. These bricks, as well as the Super High Duty ones that make up the hearth, and the Medium Duty that form our walls, expand and contract in response to temperature changes. This makes particular and thorough insulation a key element to building any oven, particularly this one.

10” triple wall stainless steel flue purchased through Woodland Direct out of Auburn Hills, MI (844-890-5061)

The second major form of insulation is this 2” ceramic blanket, which wraps around the entire oven, covering any outside exposure.

The Pilot 3000 High Temp Mortar fills every joint and becomes less brittle when exposed to high temperatures.

The white visible above the brick is ceramic fiber paper, which we used as an expansion joint.